| Step1: Master pattern making | An original master model, often produced using 3D printing or CNC machining, is created to serve as the basis for the molds. |

| Step2: Silicone mold making | A silicone mold is made from the master model. This mold is capable of reproducing the exact details of the original model. |

| Step3: Vacuum casting | The selected resin is poured into the silicone mold. The mold is then placed in a vacuum chamber, where the vacuum eliminates air bubbles and ensures that the resin fills all the mold's intricacies. |

| Step4: Curing | he mold, containing the resin, is cured in an oven or under specific temperature conditions. This solidifies the resin, transforming it into a solid plastic part. |

| Step5: Demolding | Once the resin has fully cured, the mold is carefully opened, and the prototype is removed. Any excess material or flash is trimmed off. |

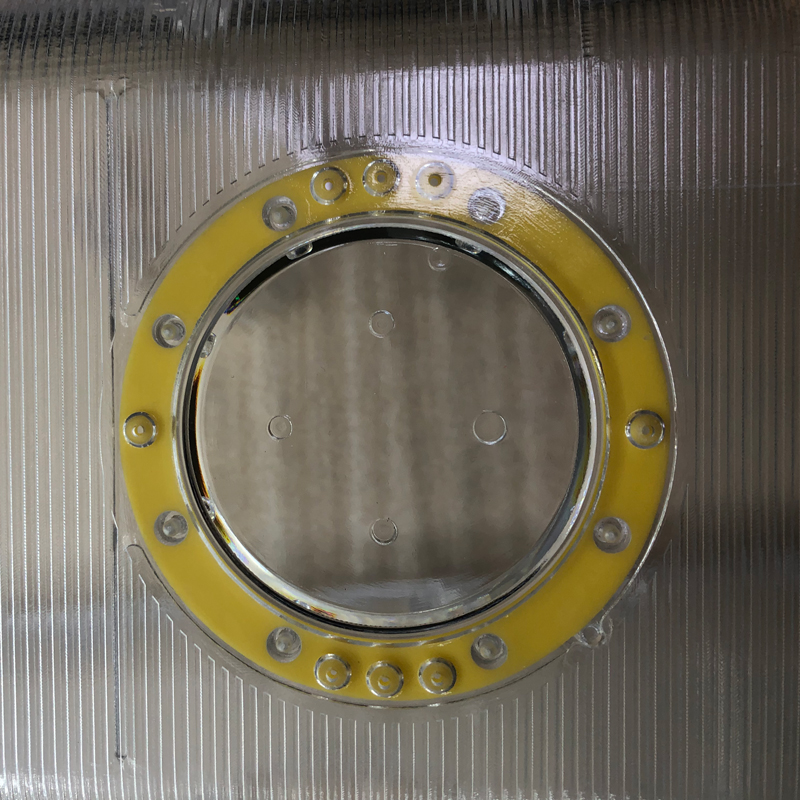

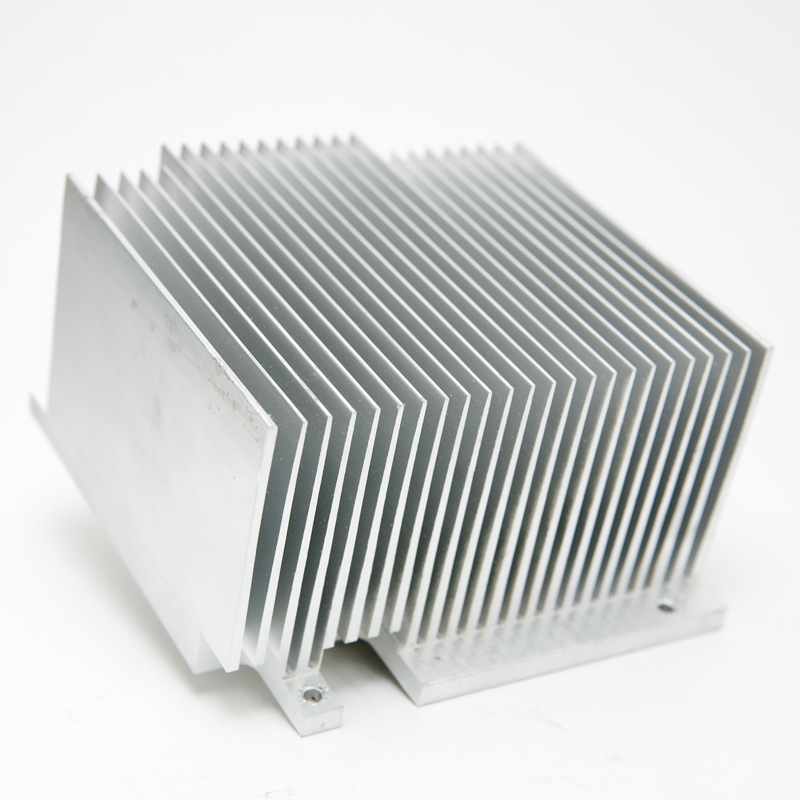

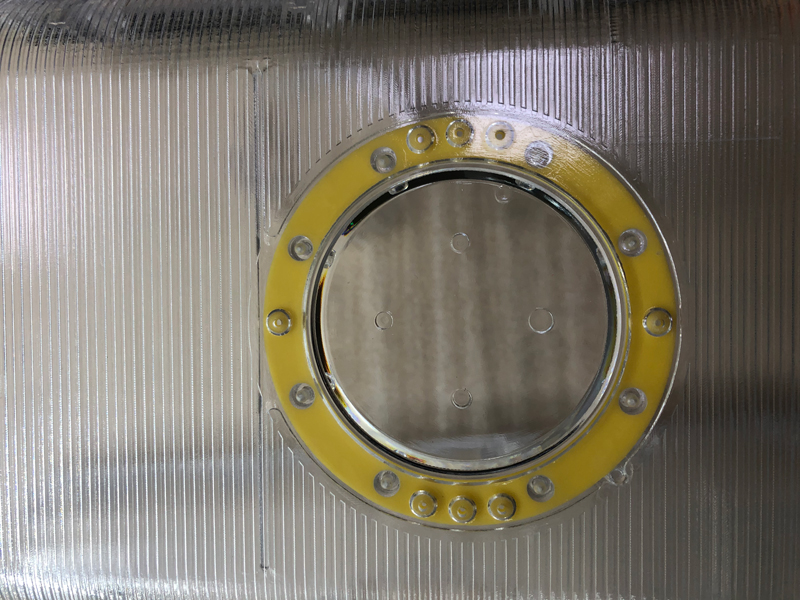

| Step6: Surface Finish | Post-processing steps, such as painting, sanding, or assembly, may be performed to achieve the desired final appearance. |

Vacuum casting is also called urethane casting or Polyurethane casting, a versatile manufacturing process used to create high-quality prototypes and small production runs of plastic parts. This technique allows for the reproduction of intricate details and surface textures, making it an ideal choice for producing functional and aesthetically appealing prototypes.

Vacuum casting is also called urethane casting or Polyurethane casting, a versatile manufacturing process used to create high-quality prototypes and small production runs of plastic parts. This technique allows for the reproduction of intricate details and surface textures, making it an ideal choice for producing functional and aesthetically appealing prototypes.| Lead time | 7-10days |

| Accuracy | +-0.05mm |

| Maximum Casting Dimension | 2200*1200*1000mm |

| Minimum Thickness | >=1mm |

| Colour | Based on client’s demand |

| Hardness | ShoreA30- ShoreA90 |

| Surface Finish | Glossy surface or Matte surface |

Vacuum casting serves as a valuable tool in various industries, particularly when creating prototypes, small-batch production, or pre-production testing: Product Design: Prototypes with functional features and aesthetics aid in design verification and refinement. Consumer Electronics: Creating realistic prototypes for devices and accessories. Automotive: Prototyping intricate interior components, such as dashboards and panels. Medical Devices: Developing prototypes for medical equipment and instruments. Art and Design: Producing artistic and sculptural pieces with complex shapes. In addition to our on-demand 3D printing and CNC machining services, we proudly offer an exceptional vacuum casting service tailored for rapid prototyping and small-batch productions. Our expertise lies in delivering high-precision casting parts swiftly, complemented by an extensive selection of materials, a diverse range of colors, and a variety of hardness options. . If you are looking for vacuum casting service, pls feel free to contact with us @[email protected], we will provide quote and professional suggestions free of charges. Urethane casting parts are good ways for custom and first-run produciton , they enable you to rest product quality before start large qty production .

Vacuum casting serves as a valuable tool in various industries, particularly when creating prototypes, small-batch production, or pre-production testing: Product Design: Prototypes with functional features and aesthetics aid in design verification and refinement. Consumer Electronics: Creating realistic prototypes for devices and accessories. Automotive: Prototyping intricate interior components, such as dashboards and panels. Medical Devices: Developing prototypes for medical equipment and instruments. Art and Design: Producing artistic and sculptural pieces with complex shapes. In addition to our on-demand 3D printing and CNC machining services, we proudly offer an exceptional vacuum casting service tailored for rapid prototyping and small-batch productions. Our expertise lies in delivering high-precision casting parts swiftly, complemented by an extensive selection of materials, a diverse range of colors, and a variety of hardness options. . If you are looking for vacuum casting service, pls feel free to contact with us @[email protected], we will provide quote and professional suggestions free of charges. Urethane casting parts are good ways for custom and first-run produciton , they enable you to rest product quality before start large qty production . Vacuum casting is a cost-effective process to ensure a accessible way of making prototypes.Create high quality prototype with various materials and deigns . Have your design tested easily and get them ready for functional testing.

Vacuum casting is a cost-effective process to ensure a accessible way of making prototypes.Create high quality prototype with various materials and deigns . Have your design tested easily and get them ready for functional testing. Ideal Vacuum casting products market , concept models , consumer testing and user evaluation . The parts turn out with high quality surface finish and end-use functionalities . Our vacuum casting service help you to incorporate changes fast for further testing and market launch .

Ideal Vacuum casting products market , concept models , consumer testing and user evaluation . The parts turn out with high quality surface finish and end-use functionalities . Our vacuum casting service help you to incorporate changes fast for further testing and market launch .

Vacuum casting is an ideal solution for making high-quality prototypes and small-batch parts . We can help you reach your manufacturing goals.